3D printing is not about just printing materials in plastic and metal, it is a whole new concept where you can print literally anything with any material. 3D printed homes are one such concept that is fast gaining traction. Currently, there are a handful of companies that are making 3D printers big enough for constructing homes, but the manufacturers of these machines are still at the prototype stage. There are also other 3D printers which are designed to construct parts to print which are then assembled on site. Nevertheless, there is a lot of experimentation with regard to construction 3D printing going on across the world.

3D printing is revolutionising many industries- medical, automotive, aviation, fashion and even food. Now, 3D printers are being set up to print entire houses and other constructions the way plastics and metals are 3D printed.

As against conventional construction methods, 3D printing/additive manufacturing a house saves a significant amount of time and money for the builder. It results in a far more accurate building without any chance of human error. However, manufacturing, assembling and installing the 3D printer for construction is quite a big challenge which is something that many experts are working on.

Development of 3D printers for concreteThe whole concept of construction 3D printing is a fairly recent phenomenon. Prior to that, the technology used wasn’t mature enough to handle 3D printing on a large scale.

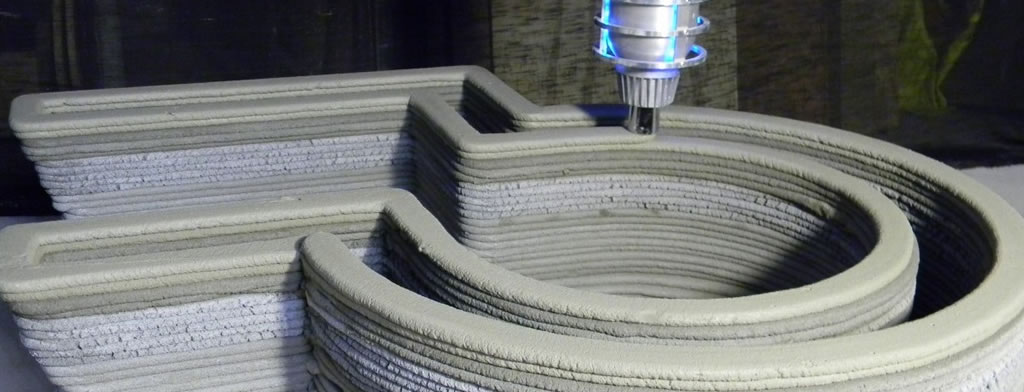

The Loughborough University in England was one of the first to dedicatedly research the possibilities of 3D printing with concrete. They started in 2008 and have now developed a 3D printer which can construct concrete material with dimensions that are impossible to make with traditional techniques. They have developed robotic 3D printers that precisely extrude concrete in a pre-decided manner successively to get the desired result.

As against conventional methods, 3D printing with concrete gives you certain unique benefits-

Speed - A 3D printer can print with concrete at speeds not possible with regular methods. In fact, some companies have even 3D printed homes within a span on 24 hours

Affordability - 3D printing allows you to build houses which are much more cost-effective than conventionally built ones. This would be great to build homes for the economically backward sections of society

Strength and Durability - 3D printed homes are designed to resist any kind of natural calamity. It is also possible to create strong foundations with 3D printing technologies.

Design Possibilities - 3D printing offers you immense design possibilities which isn’t possible with traditional construction methods. This opens the door for creating amazing building by marrying the art of design with the science of construction.

What’s in store for 3D printing in concrete for the futureThere is no doubt that 3D printing with concrete is the next big trend in the construction sector. However, the technology hasn’t matured enough for large-scale deployment across the world, though there are obvious advantages. Till then, startups and companies dealing with construction 3D printing are slowly harnessing the power of this medium to create something that will one day change the course of human history.